You must have gone to the movies with 3D effects, wearing special glasses to see the action in an all-round manner. 3D design and modelling have been a superior technology that has provided solutions in various fields. From the market crashing gaming sector to the medical industry, 3D modelling and imaging have been used to make hypnotic CGI characters and to see through a patient’s body to save them. 3D technology has been here for a long time, but it got to the common public pretty late. Now everyone has a use for 3D tech in a different sector. 3D modelling has reached higher standards in framing things for humanity. You can now not only design shapes using the 3D tech you can also print out the object that you have designed using the new-age 3D printers. 3D printers use moulding or polymer materials to print the whole object that you have developed on the application.

3D technology, as you know, is used for video-gaming on a large scale. So when the artists are creating these games, that shows a whole city on a visual screen, they are constructing trees, people, buildings and even entire cities using the same technology. If structures can be created to be seen on the screen, then they can also be designed in order to make them a reality. 3D technology can benefit modular construction by giving options to the design team so that the work can be efficient and faster. Let’s see what those options are.

How Does 3D Design Help Construction?

The basic 3D modelling tech allows you to create simple polygon shapes that include cones, pyramids, cubes, spheres, etc. This basic program can be used to develop designs for single-story houses with basic designs. For more complex building designs, a more complicated 3D design application is used, which is the non-uniform rational b-spline or NURBS. These kinds of application can give you streamline shapes and bezel curves that can be used to design complicated building structures — designing buildings with unique extensions and arches.

Automation has become primary for everything we buy from food to furniture to toilet paper. But the construction industry is still under the same processes of doing things by hand for the most part. Most of the time, the buildings to be constructed are designed as blueprints that are in 2D format. The designing process becomes slower and inefficient due to this technique. The 2D diagrams never show you the other side of the view that you’re getting on 2D. Handmade 2D blueprints develop a lot of errors during the main construction because the design created got unrealistic at places and would look out of place. 3D imaging, on the other hand, gives you a better idea of the design by letting you create independently from all the possible perspectives of the building. This allows more accurate calculations for materials and prevents wastage. Here are the factors that can be advantageous when using 3D imaging for modular construction.

Extensive Space for Creation

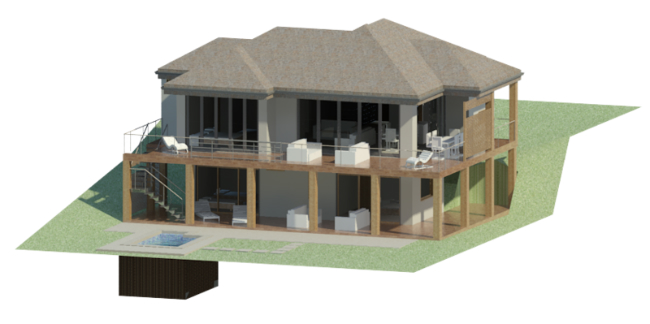

Applications being developed in today’s technology are far more superior than what we had a decade ago. The heavy technicalities of designing a blueprint in the 2D format are taken away by the 3D imaging software and the ease of use in them. A 3D design will let you examine a building design in the same way it would appear in the real world. This removes the hassle of trying out different designs after stopping the construction midway when a structure doesn’t work well with the design. This gives the architect the freedom to design with creativity without having to create several blueprint designs. The 3D image makes it easy to perceive the design of the building and determining how it would turn up during the modular construction process. 3D imaging gives you the space to come up with uniqueness in the structure and be more experimental.

Self Explanatory Designs

When an architect makes a blueprint of any design, it has to be explained to the CEO of the construction company due to the intricate technicalities of the blueprint method. With the 3D layouts, the designs become self-explanatory, as the structures of the building are displayed as they would come out after the construction is complete. Also, the plans can be easily shared with the other team members who will quickly get an idea of the designs.

Earlier Error Identification

Blueprint designs make it difficult to predetermine the errors that might occur during construction. The 2D layout gives a lesser idea of the finished product. While the construction goes on, some of the parts may have flaws in the actual build, hence costing you time and money to fix it back. With 3D imaging, you can rest assured that the errors will be rectified before they trouble your team members on the real construction site. When you build a 3D image of the structure, you can rotate it and view it from all angles for defects. This allows you to take opinions from other people that are on your team. Pointing out mistakes in the design becomes easier for everyone when you remove the technicalities of the 2D blueprint planning.

Efficient Synergy

Simplifying the complex technical diagrams on a blueprint is the main task of a 3D modelling program. The designs of modular construction that are drawn on the blueprints don’t allow you to contemplate what the final build is going to look like. Such models can only be examined after the parts have been put together, and structures have been assembled. If a module doesn’t conform with the other structures, there might be issues with airtightness and durability of the structure. To eliminate errors, there must be proper collaboration among the team members who are overseeing respective processes. 3D modelling makes it possible to keep all team members in the loop and sync updates with every minimum change or flaw in the design. This efficiency that develops during the design process is done by viewing the whole building design from the inside out. Every person working at every part of the building can redirect the sign of a defect to the other members working on the different areas of the structure. The design can be instantly changed or rescheduled.

Modular construction becomes more streamlined with the use of 3D modelling, and more speedy installation takes place. To get 3D modelling help contact Cormode & Dickson.